Is the focus on single-use plastics harming efforts to raise awareness of recycling other materials?

A blog by Antonia Grey, BMRA's Head of Policy and Public Affairs.

When the Resources and Waste Strategy was launched, accompanied by much fanfare in 2018, I was thrown into a slough of despond. It seemed to me that there was only one resource that mattered… single-use plastic. Yes, single-use plastic is a blight on the natural environment but so too is open cast mining for metal. And yet, as a recyclable resource and one of the only permanent materials, metal was mentioned just seven times. I know because I counted. [A side note: durable plastic, of the kind found in end-of-life vehicles and waste electrical and electronic equipment fared little better.]

In his forward, the then Secretary of State for Environment, Food and Rural Affairs, Michael Gove, said: “The Government’s ambitious new Resources and Waste Strategy seeks to redress the balance in favour of the natural world. Our goal is to move to a more circular economy which keeps resources in use for longer – for that to happen, we must all reduce, reuse and recycle more than we do now.”

Since then, the only resource to really be talked about and targeted is plastic. Nothing has been done to increase or even promote the use of recycled metals in new products or infrastructure projects. Even easy-win, green procurement policies as called for the BMRA, have not been adopted.

We are not alone in our demands. Recently, environmental policy think tank Aldersgate Group called for changes to building and waste

regulations and the introduction of targets for recyclable material suggesting that (around 90% of end-of-life steel could be collected and recycled in electric arc furnaces). Of course, then we then hit the issue of a lack of capacity.

As a sector, we are really good at recycling stuff from ELV and WEEE to construction waste and even decommissioned railway track. We are so successful, in fact, that we have to export over 80% of metal arisings because there is not enough domestic capacity to take what we process.

To solve this issue, the Aldersgate Group seemingly suggested that to drive resources efficiency, the Government in turn needs to make access to innovation funding, such as through the Industrial Energy Transformation Fund, easier by simplifying timelines and allowing businesses to apply for funding on a rolling basis.

It also suggests that the UK needs to move towards competitive industrial electricity prices. However, even though it knows UK industries face significantly higher industrial electricity prices than European competitors, the Government seems reluctant to get involved.

With the Environment Bill delayed again, and policy seeming to continue to cleave to tackling single-use plastics, and almost exclusively single-use plastics, I have little faith that much is set to change. And that is so disappointing.

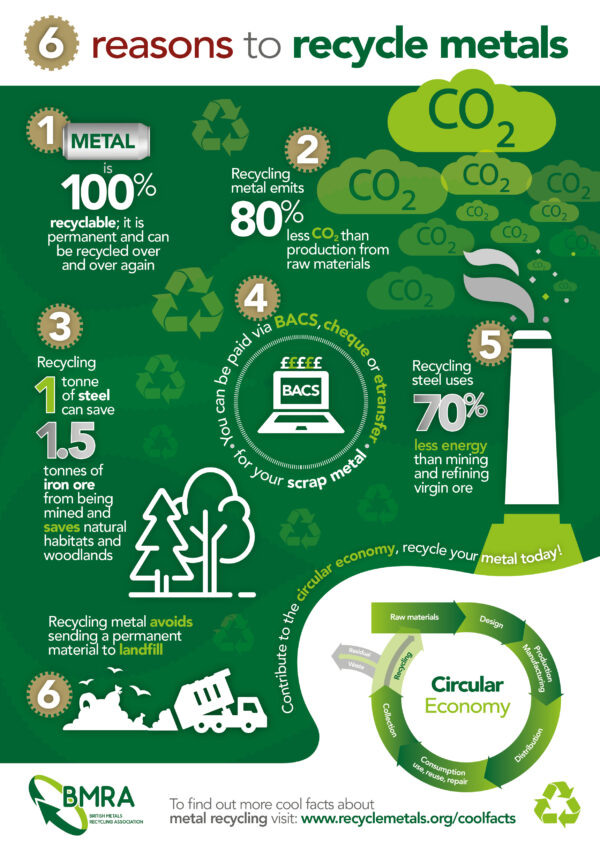

The data supporting the use of recycled metals makes for a compelling argument for change and yet it seems that data is not being absorbed. Every tonne of recycled steel saves 1.5 tonnes of iron ore and 0.5 tonnes of coal. It uses 70% of the energy and 40% of the water and the saving in CO2 emissions are even better at 75%.

The figures for aluminium and copper are even more impressive. The recycling of copper requires up to 85% less energy than primary production. Around the world, this saves 40 million tonnes of CO2. Recycling aluminium uses 95% less energy than producing aluminium from raw materials and saves 97% of greenhouse gas emissions produced in the primary production process.

Surely these data on their own should be enough to have Governments around the world, not just in the UK, devote a laser-like focus on the climate win that is recycling metals?