CEO letter to members

Dear colleagues

It cannot have escaped your attention that our sector is suffering from an ever-increasing number of fires. It seems an endless stream of waste batteries, in particular lithium-ion batteries, are finding their way into scrap loads.

At the same time, I am hearing more reports of cylinders also finding their way into the supply chain, increasing the risk of deflagrations should they find their way into a fragmentiser.

While in some cases, these materials are deliberately concealed within the scrap, often they are included accidentally because either the supplier, or the supplier’s supplier, has not segregated them at source.

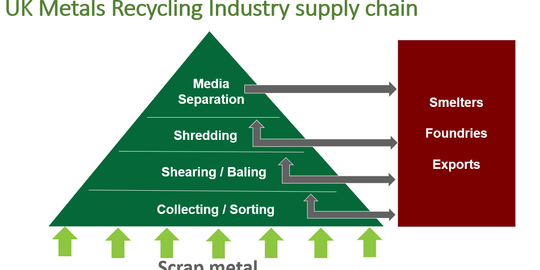

These materials create risks of fire, explosion and toxic poisoning at metal recycling yards, steelworks and foundries, and even within the transport system. We must, therefore, take steps to ensure the safety of staff and visitors, the integrity of facilities and the safety of those who transport and process our materials.

For these reasons, I am re-issuing the BMRA’s quality document entitled Guidance regarding new acceptance criteria for bulk UK ferrous scrap to improve quality and safety throughout the supply chain. Click here to download your copy.

This Guidance is supported by the shredder operators listed in the document. These operators, all of whom are members of BMRA, have established a set of acceptance criteria to confirm the types of material that must be excluded from the recognised bulk ferrous scrap grades. These companies have committed to adopting these acceptance criteria to bulk ferrous scrap grades they receive.

However, as CEO of the BMRA, I would like to invite all member companies to support this document. With this in mind, I intend to re-issue the document next year with a complete list of companies who have signed up to support our drive to improve the safety and quality of UK scrap.

Yours sincerely,

James Kelly

CEO

BMRA

It cannot have escaped your attention that our sector is suffering from an ever-increasing number of fires. It seems an endless stream of waste batteries, in particular lithium-ion batteries, are finding their way into scrap loads.

At the same time, I am hearing more reports of cylinders also finding their way into the supply chain, increasing the risk of deflagrations should they find their way into a fragmentiser.

While in some cases, these materials are deliberately concealed within the scrap, often they are included accidentally because either the supplier, or the supplier’s supplier, has not segregated them at source.

These materials create risks of fire, explosion and toxic poisoning at metal recycling yards, steelworks and foundries, and even within the transport system. We must, therefore, take steps to ensure the safety of staff and visitors, the integrity of facilities and the safety of those who transport and process our materials.

For these reasons, I am re-issuing the BMRA’s quality document entitled Guidance regarding new acceptance criteria for bulk UK ferrous scrap to improve quality and safety throughout the supply chain. Click here to download your copy.

This Guidance is supported by the shredder operators listed in the document. These operators, all of whom are members of BMRA, have established a set of acceptance criteria to confirm the types of material that must be excluded from the recognised bulk ferrous scrap grades. These companies have committed to adopting these acceptance criteria to bulk ferrous scrap grades they receive.

However, as CEO of the BMRA, I would like to invite all member companies to support this document. With this in mind, I intend to re-issue the document next year with a complete list of companies who have signed up to support our drive to improve the safety and quality of UK scrap.

Yours sincerely,

James Kelly

CEO

BMRA